Formaldehyde-free environmentally friendly glass wool board

Summary: Formaldehyde-free environmentally friendly glass wool is based on traditional centrifugal glass wool, with some adjustments made to the raw material formula and forming process of the glass wool, making the original wool suitable for bonding and curing with new types of adhesives.

What is formaldehyde-free environmentally friendly glass wool?

Formaldehyde-free environmentally friendly glass wool is based on traditional centrifugal glass wool, with some adjustments made to the raw material formula and forming process, making the original wool suitable for bonding and curing with new types of adhesives.

The adhesive used in formaldehyde-free environmentally friendly glass wool is completely different from traditional glass wool; it is an acrylic adhesive. It completely eliminates toxic and harmful substances such as phenol, formaldehyde, and urea, thus representing a revolution in traditional glass wool. Since we not only solved the adhesive problem but also addressed the curing issue during production and cost control, Sound Guard has successfully produced high-density formaldehyde-free glass wool (with a maximum density of 120kg/m³), becoming one of the few manufacturers in the world that can simultaneously produce both low-density and high-density formaldehyde-free environmentally friendly glass wool products. This is the real reason why many international companies are seeking technical, production, and sales cooperation, even exclusive sales cooperation, with Sound Guard.

Disadvantages of traditional glass wool

Due to the use of phenolic resin as the main adhesive in traditional glass wool products, it is inevitable that harmful substances such as free formaldehyde, phenol, and urea exist in the glass wool. Although the formaldehyde content meets current domestic standards, producing completely formaldehyde-free glass wool products has always been the direction of effort for major glass wool manufacturers both domestically and internationally.

Comparison of formaldehyde-free environmentally friendly glass wool and traditional glass wool

| Traditional glass wool | Formaldehyde-free environmentally friendly glass wool |

| Meets national standards, contains low doses of formaldehyde (formaldehyde release amount: test results between 0.8-1.5mg/L) It is between 0.8-1.5 mg/L. | Does not contain formaldehyde, ammonia, phenol, and other harmful substances (formaldehyde test results: Cái昧 伺钴). |

| The average diameter of the inner layer glass fibers is 12-18 μm. | Appearance: yellow, pink, feels rough to the touch, with a slight prickly sensation |

| Appearance: white exterior, aesthetically pleasing, clean, and feels very soft and comfortable | Under the same temperature conditions, high thermal conductivity |

| Example: Duct board 80kg/m³ (25℃) thermal conductivity 0.043 Under the same temperature conditions, low thermal conductivity | Duct board 80kg/m³ (25℃) thermal conductivity 0.033 New generation of formaldehyde-free environmentally friendly glass wool boards |

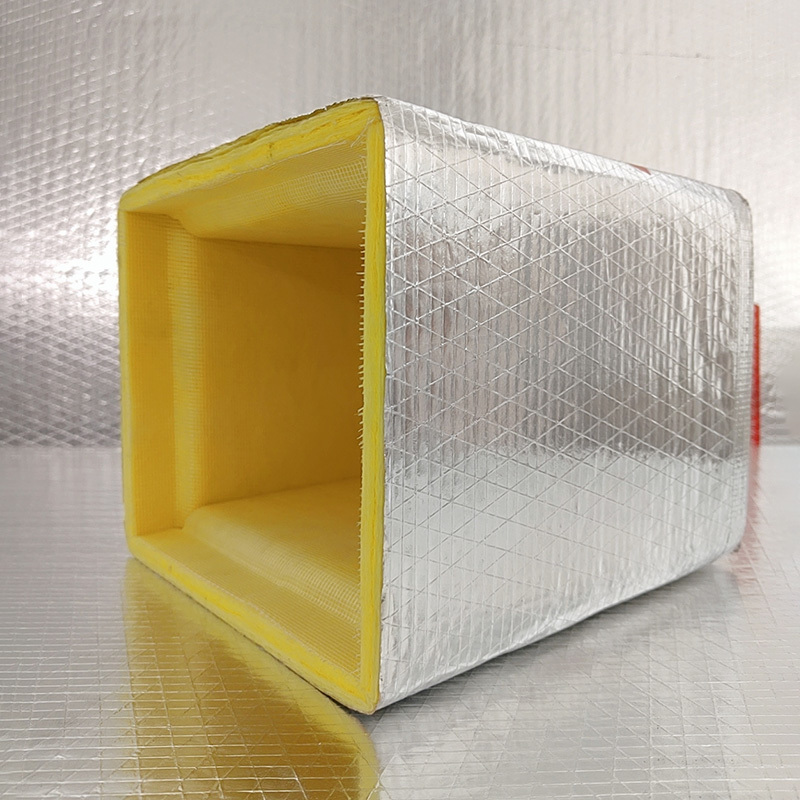

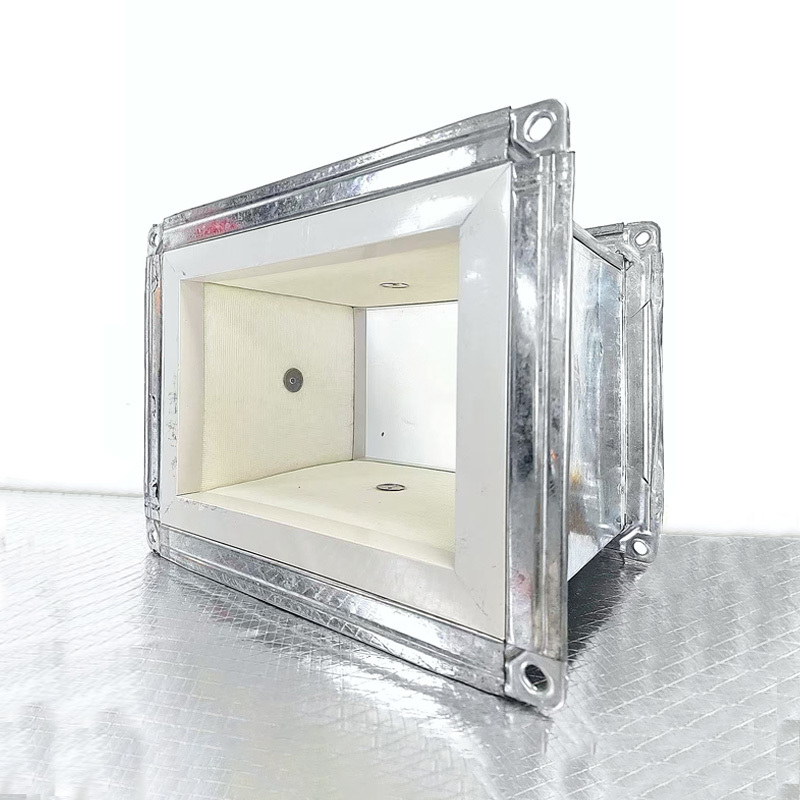

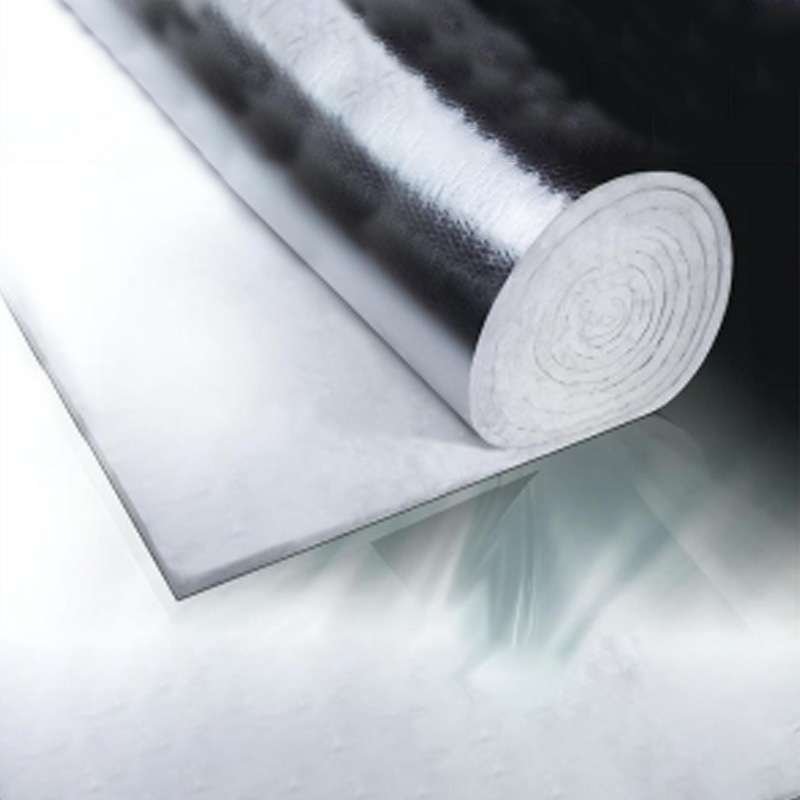

Formaldehyde-free environmentally friendly centrifugal glass duct boards are made from inorganic natural minerals such as quartz sand, dolomite, and borax, which are melted at high temperatures and bonded together using acrylic thermosetting resin, produced using advanced production lines.

Product types

| Density (kg/m³) | Thickness (mm) | Length (mm) | Width (mm) | Cotton board |

| 20~100 | 10~100 | 1200~2000 | ☆ Special specifications are welcome to inquire by phone. ☆ Various surface layers can be added to the product surface upon user request. | 600 |

Advantages and characteristics

· Does not contain harmful substances such as formaldehyde, ammonia, and phenol — the acrylic thermosetting resin added to the board mainly consists of basic polymers, tackifying resins, waxes, fillers, plasticizers, and antioxidants.

Good thermal insulation effect — the average fiber diameter of centrifugal glass wool is 5-8 microns, evenly distributed, with good resilience, not forming slag balls, and has excellent physical and thermal resistance properties.

Non-corrosive — the pH value of the product is 7.5-8.0, slightly alkaline, with stable and lasting performance, and will not cause rust or other adverse phenomena on metals it contacts.

More environmentally friendly products — the board surface is flat and beautiful, preventing the shedding of glass fibers, and after applying a layer of acrylic coating, it has better anti-mold, antibacterial, and moisture-proof functions, making the product more environmentally friendly.

High water repellency — the product can resist the intrusion of moisture in the air during long-term use, which can extend the product's lifespan.

Fire resistance — over 90% of its raw materials are natural inorganic minerals, fireproof and moisture-proof. According to the National Fire Building Materials Quality Inspection Center, based on GB.S1/174-2006, the product is classified as A1 non-combustible building materials.

Application scenarios

HVAC systems — used for duct insulation.

New and renovated buildings — wall insulation, decorative ceilings, specially made outer building wall panels, room partitions.

Ships and trains — wall insulation, room partitions, interior ceilings, etc.

Ordinary buildings — ideal insulation materials for brick and concrete structures, used in various commercial or public buildings such as shopping centers, banks, and malls.

Theater — black-coated glass wool boards can absorb sound and light, eliminating stage echoes.

Various pump rooms, machine rooms — insulation and sound absorption.

Product specifications

Thermal insulation performance thermal conductivity (20℃)

| Density (kg/m³) | Thickness (mm) | Length (mm) | Width (mm) | Cotton board |

| 20~100 | 10~100 | 1200~2000 | ☆ Special specifications are welcome to inquire by phone. ☆ Various surface layers can be added to the product surface upon user request. | 600 |

Density kg, m³

| Thermal conductivity w/m. k | 24 | 32 | 40 | 48 | 64 | 80 | 96 |

| 导热系数w/m. k | 0.036 | 0.035 | 0.034 | 0.033 | 0.032 | 0.032 | 0.032 |

Physical performance indicators

| Performance | Testing methods | Technical requirements |

| Density | GB/T5480.3 | 24~100kg/m³ |

| Average fiber diameter | GB/T5480.4 | 5 to 8 micrometers |

| Water repellency rate | GB/T10299 | ≥98% |

| Thermal weight shrinkage temperature | GB/T11835-1998 Appendix D | >=250℃ |

| Clinker ball content | GB/T5480.5 | 0% |

| Fire performance | GB8624 | Non-combustible Class A |

| Corrosion resistance | ASTMC665 | Meets requirements |

| Anti-mold property | HG/T3950-2007 | No mold growth |

| Moisture absorption rate | GB/T5480.7 | <5% |

Sound absorption coefficient (JC/T469-2005)

| Density (kg/m³) | Length (mm) | Noise coefficient |

| 24, 32, 40 | 50 | 06~0.8 |

| 75, 100, 150 | >0.8 | |

| 48, 64, 80, 96 | 12, 15 | 0.4~0.6 |

| 20, 25 | 0.6~ 0.8 | |

| 40, 50 | >0.8 |

☆The above sound absorption coefficients using the reverberation method are the average values at frequencies of 250, 500, 1000, and 2000 Hz.

Classification:

Keyword: Formaldehyde-free environmentally friendly glass wool board

Recommend Products

Message

If you have any form of cooperation intention, welcome to leave your information here, we will contact you soon.