Formaldehyde-free environmentally friendly glass wool felt

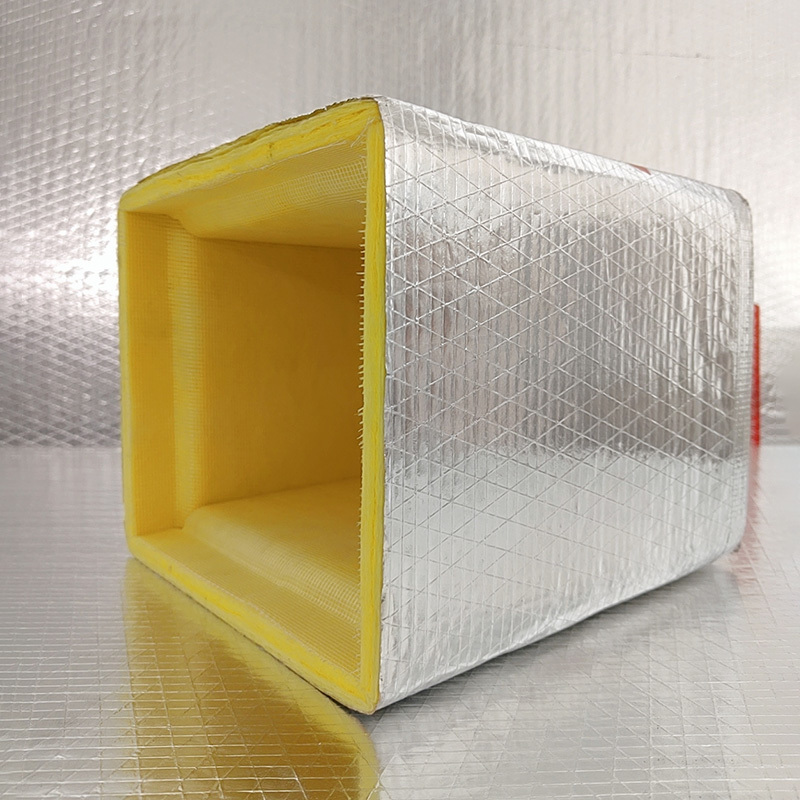

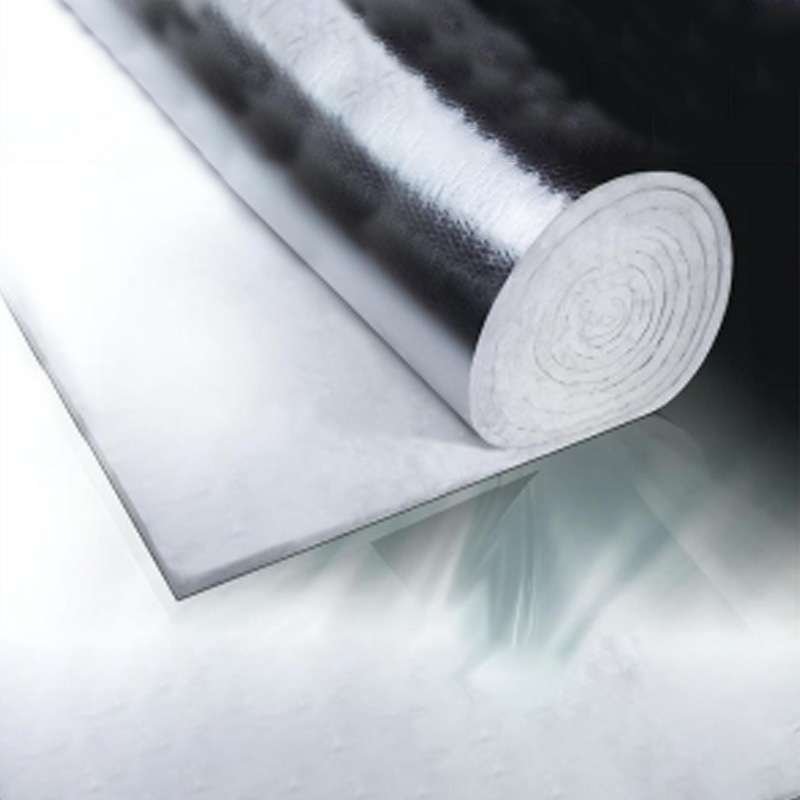

Summary: Formaldehyde-free environmentally friendly glass wool felt is a flexible mat product made by bonding fine glass fibers together with acrylic thermosetting adhesives, which are then heated and pressed.

Formaldehyde-free environmentally friendly glass wool felt is a flexible felt product made by bonding slender glass fibers together with an acrylic thermosetting adhesive, which is heated and pressed.

Product Advantages

Free of harmful substances such as formaldehyde, ammonia, and benzene

Good thermal insulation effect

Durable noise reduction

Non-corrosive

Strong elasticity

Good flexibility

Class A non-combustible

Product Applications

Wood structure buildings - residential and commercial buildings

Metal structure buildings - commercial buildings, steel structure factories

Ceiling suspension systems - backfill treatment for newly built ceilings or ceiling systems in renovated buildings

Inside buildings - can provide thermal insulation and soundproofing treatment for combinations of interior walls, floors, ceilings, and basements.

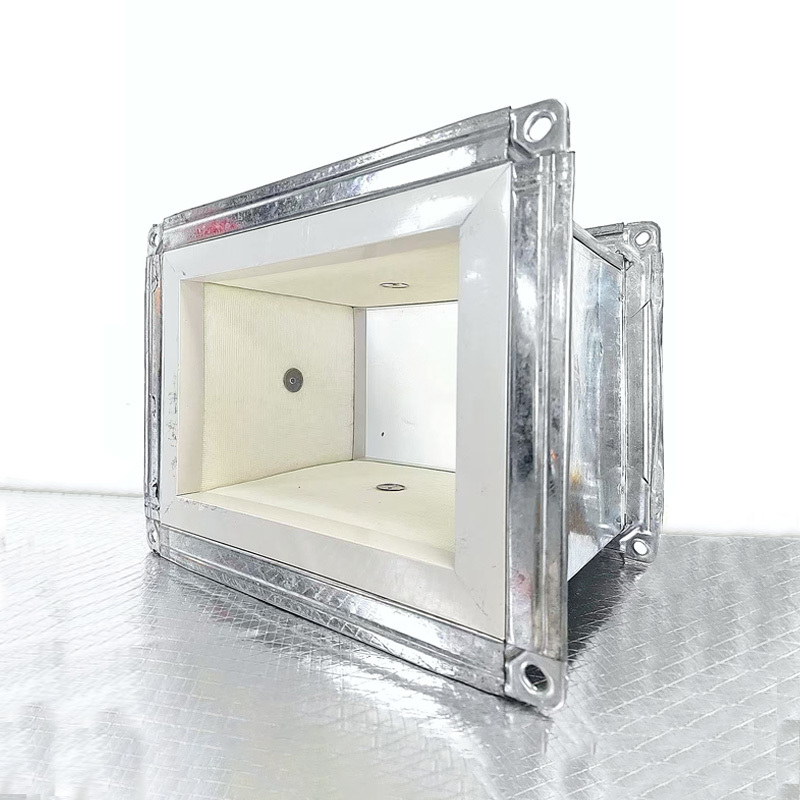

Air conditioning systems - insulation of air supply hoses and duct flanges, thermal insulation and sound absorption for various tanks and equipment.

Product Types

Strip felt - used for standard and other wall cavities, can be installed faster compared to roll products.

Roll felt - can be cut to any size for wall cavities, installed in any part of the building, especially in long and unobstructed areas, such as steel structure roofs, grooves for electrical conduits, and water pipes.

Product Specifications

| Product Types | Density (kg/m³) | Thickness (mm) | Length (mm) | Width (mm) |

| Roll felt | 10~48 | 50, 75, 100 | 5500, 11000, 20000 | 1200 |

| Strip felt | 10~48 | 50, 75, 100 | 1200 | 600 |

Physical Performance Indicators

| Performance | Testing Method | Technical Requirements |

| Density | GB/T5480.3 | 10~48kg/m³ |

| Average fiber diameter | GB/T5480.4 | 5 to 8 micrometers |

| Water repellency | GB/T10299 | ≥98% |

| Thermal weight shrinkage temperature | GB/T11835-1998 Appendix D | ≥250C |

| Slag ball content | GB/T5480.5 | 0% |

| Fire performance | GB8624 | Non-combustible Class A |

| Corrosion resistance | ASTM C665 | Meets requirements |

| Mold resistance | HG/T3950-2017 | No mold growth |

| Moisture absorption rate | GB/T5480.7 | ≤5% |

Thermal insulation performance / thermal conductivity (25℃)

| Density kg/m³ | 10 | 12 | 14 | 16 | 20 | 24 | 32 |

| Thermal conductivity w / mk | 0.046 | 0.043 | 0.041 | 0.040 | 0.038 | 0.036 | 0.035 |

R-thermal resistance value (25℃)㎡K/W

| Thickness Density | 10 | 12 | 14 | 16 | 20 | 24 | 32 |

| 50 | 1.08 | 1.16 | 1.22 | 1.25 | 1.32 | 1.39 | 1.43 |

| 75 | 1.63 | 1.74 | 1.83 | 1.88 | 1.97 | 2.08 | 2.14 |

| 100 | 2.71 | 2.33 | 2.44 | 2.5 | 2.63 | 2.78 | 2.86 |

☆Thermal resistance = Thickness (m) / Thermal conductivity

Sound absorption coefficient

| Density (kg/m³) | Thickness (mm) | Noise coefficient |

| 10, 12 | 50 | 0.6~0.8 |

| 75, 100, 150 | >0.8 | |

| 16, 20 | 25 | 0.4~0.6 |

| 40, 50 | 0.6~0.8 | |

| 75, 100 | >0.8 | |

| 24, 28, 32 | 25, 40 | 0.6~0.8 |

| 50, 75, 100 | >0.8 |

☆The above sound absorption coefficients measured by the reverberation method are the average values at frequencies of 250, 500, 1000, and 2000 Hz.

Classification:

Keyword: Formaldehyde-free environmentally friendly glass wool felt

Recommend Products

Message

If you have any form of cooperation intention, welcome to leave your information here, we will contact you soon.