What are the common problems in the production of ventilation ducts?

Release time:

2025-02-10

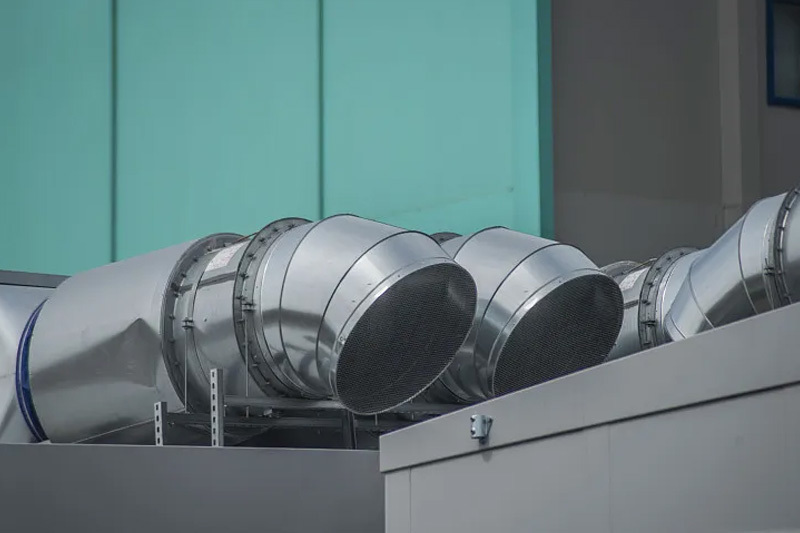

Ventilation ducts are metal or non-metal pipes used in ventilation and air conditioning engineering for industrial and civil buildings. They are a type of municipal infrastructure designed to facilitate air circulation and reduce the concentration of harmful gases. Most ventilation ducts are made using duct processing equipment. However, due to various reasons, there may be issues with the processed ducts. Below, the editor from Kexing will take you through the common problems.

Ventilation ducts are metal or non-metal pipes used in ventilation and air conditioning engineering for industrial and civil buildings. They are a type of municipal infrastructure designed to facilitate air circulation and reduce the concentration of harmful gases. Most ventilation ducts are made using duct processing equipment. However, for various reasons, the processed ducts may have issues. Below, the editor from Kexing will help us understand what these problems are.

1. Processing materials do not meet standards

a. Performance: The surface of the sheet is uneven, the thickness is inconsistent, and there are obvious indentations, cracks, sand holes, scars, and rust; the flat surface of the duct sinks, and the sides bulge outward, showing obvious deformation.

b. Impact: During operation, the duct leaks air, increasing the air conditioning load, while the lifespan and performance of the duct are affected.

c. Cause: The materials are unqualified and cannot meet the requirements for making ducts.

d. Measures: Before using duct processing equipment to make ducts, check the factory qualification certificate and material quality proof, as well as the appearance thickness, to ensure the materials are usable.

2. Duct corners and elbow angles are inaccurate

a. Performance: The two opposite planes of the rectangular duct and the two end faces are not parallel; the corners are not straight; the diagonals are not equal; the seams are not tight.

b. Impact: This can cause uneven stress on the duct connections, resulting in non-straight ducts after installation, loose flange gaskets, system air leaks, leading to air conditioning load loss, and shortening the lifespan.

c. Cause: The sheet cutting layout is inaccurate; the ducts are parallel, but the lengths and widths of the opposing sheet materials are not equal.

d. Measures: When unfolding the cutting, the sheet material should be strictly squared, and the length, width, and diagonal of each sheet should be checked to keep their deviations within acceptable limits; after cutting, the two sheets of the opposing duct should be overlapped to check the accuracy of the dimensions.

Therefore, to produce practical, durable, and high-quality ducts, sufficient preparation before and after operating the duct processing equipment must be done to ensure everything is foolproof and reduce unnecessary losses.