Formaldehyde-free environmentally friendly soundproof duct - energy-saving and environmentally friendly, continuously promoting the development of green buildings.

Release time:

2025-02-12

Formaldehyde is a colorless gas with a pungent odor. In modern construction projects, formaldehyde pollution has always been a topic of concern because it not only relates to the quality of our living environment but also directly affects people's health. To avoid formaldehyde pollution, improve indoor air quality, and enhance living conditions, green buildings have emerged.

Formaldehyde is a colorless gas with a pungent odor. In modern construction projects, formaldehyde pollution has always been a topic of concern because it not only relates to the quality of our living environment but also directly affects people's health. To avoid formaldehyde pollution, improve indoor air quality, and enhance living conditions, green buildings have emerged.

Green buildings can better handle the relationship with nature under the premise of being people-oriented, achieving energy conservation and carbon reduction, while also meeting people's pursuit of a better life. As an important component of the ventilation system in green buildings, the material and performance of air ducts are particularly important.

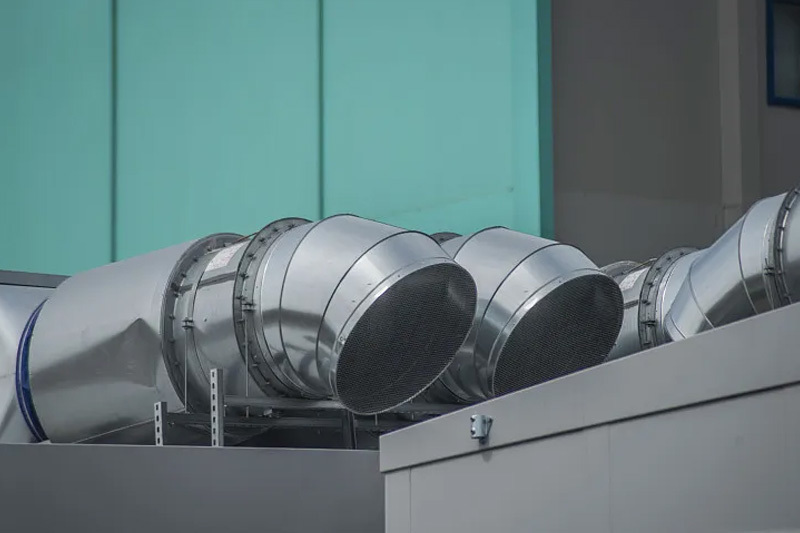

Air ducts are the duct systems used for air transport and distribution in large buildings, so dust can accumulate in the ducts, and condensation issues can arise due to the circulation of hot and cold air. In green buildings, air ducts not only need to be free of formaldehyde and achieve sound absorption and noise reduction, but they also need to have fire resistance, moisture resistance, and anti-mold properties.

Formaldehyde-free environmentally friendly sound-absorbing air ducts are a new type of green building material. The production materials and processes do not generate formaldehyde, and due to the characteristics of the materials used, these ducts have sound absorption, noise reduction, thermal insulation, moisture resistance, and anti-mold properties.

Environmentally friendly materials and processes

The main raw materials of formaldehyde-free environmentally friendly sound-absorbing air ducts are the outer layer of galvanized steel and the inner layer of formaldehyde-free environmentally friendly glass wool, both of which do not contain formaldehyde.

Among them, galvanized steel can protect the air duct's stability, making it less prone to deformation and more durable; while formaldehyde-free environmentally friendly glass wool, as the lining material of the air duct, completely eliminates toxic and harmful substances such as phenol, formaldehyde, and urea during production. Therefore, when used in formaldehyde-free environmentally friendly sound-absorbing air ducts, it not only ensures fresh and pollution-free indoor air but also reduces environmental pollution, improves living conditions, and provides ideal ecological and health benefits.

Significant sound absorption and noise reduction performance

Formaldehyde-free environmentally friendly sound-absorbing air ducts have good sound absorption and noise reduction effects, which are closely related to the glass wool lining.

This lining material, as a porous material, has internal fibers that are fluffy and interlaced, containing a large number of tiny pores. When sound encounters the porous glass wool material, it can enter the structure through the small holes, causing the air within the pores and the material itself to vibrate. The friction and viscous effects of the air convert the vibrational energy (i.e., sound energy) into thermal energy, thereby attenuating the sound energy, resulting in good sound absorption and noise reduction characteristics.

Good moisture resistance and anti-mold performance

The moisture resistance and anti-mold performance of the formaldehyde-free environmentally friendly sound-absorbing air duct material are also very good. The formaldehyde-free glass wool used has advantages such as lightweight, high fire rating, high water repellency, corrosion resistance, and stable chemical properties. Its good water repellency and corrosion resistance help maintain stable air temperature within the duct, significantly reducing condensation issues.

During the production of this air duct, a layer of white antibacterial mesh fabric made from antibacterial materials is also attached to the surface of the lining material. This mesh fabric has been treated with a special process to inhibit the growth of bacteria and microorganisms, protecting the inner wall of the duct from erosion caused by dust and dirt due to improper maintenance of the filtration system, and reducing the proliferation of microorganisms on the duct's inner wall. It can also be cleaned with a regular duct cleaning machine.