What is glass wool

Release time:

2025-02-12

Glass wool is made from glass as the main raw material, which is melted at high temperatures into fibers, mixed with an appropriate amount of binder, and then solidified.

Glass wool is made from glass as the main raw material, melted into fibers at high temperatures, mixed with an appropriate amount of binder and solidified.

It can be widely used in industries such as shipbuilding, metallurgy, electricity, and construction, with good thermal insulation and soundproofing effects. It is easy to install and has more obvious energy-saving effects.

Glass wool has advantages such as low thermal conductivity, good breathability, and high combustion performance ratings. It can be used in energy-saving insulation projects for residential and public buildings, including external wall insulation, opaque curtain wall insulation, and fire insulation zones in EPS external insulation systems.

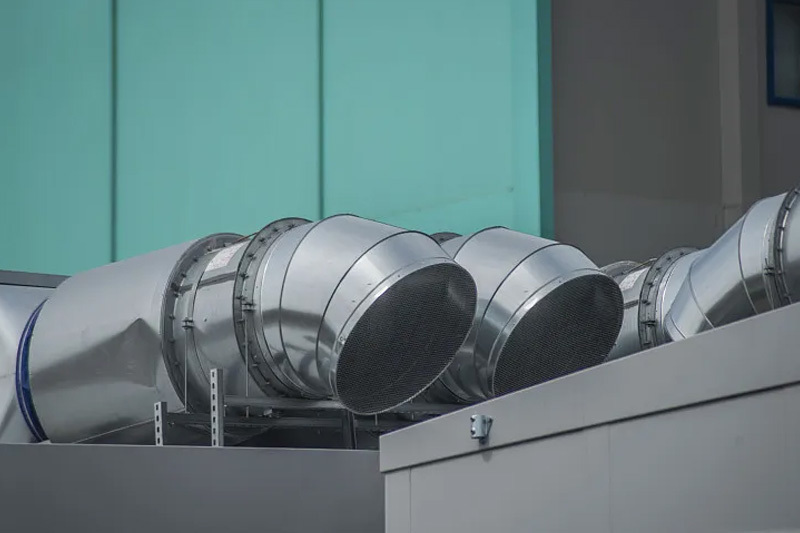

As one of the excellent insulation materials currently available, glass wool has a small thermal conductivity, good insulation performance, and saves space and materials. It is widely used in air conditioning and heating pipeline equipment.

Currently, this material has a good market space, and the development prospects of large glass wool production enterprises are very promising. Glass wool is widely used in sealing, vibration reduction, thermal insulation, soundproofing, ion exchange, and many other aspects.

It plays a wide role in industries such as automobiles, instruments, home appliances, and packaging. Its shapes include board shape, strip shape, pipe shape, washer shape, etc., with various specifications available for selection, and the shapes vary.

Centrifugal glass wool has many advantages in production technology. It is made from glass wool and other materials mixed through foaming. As an insulation material, it can be widely used in fields such as water heaters, air conditioning, and heating.

Importantly, it has low thermal conductivity, is not easily lost, is environmentally friendly and low carbon, making it very suitable for the needs of the modern market. Its plasticity is strong. It can be processed into glass wool felt according to actual needs. It saves space, reduces costs, and avoids unnecessary waste.

: Next Page

Next page: